The Process We Follow

Expert Arc Flash Risk Assessment in Belgium NFPA 70E & IEEE 1584 Compliant Solutions

At VB Engineering, we specialize in delivering end-to-end Electrical Arc Flash Risk Assessment services that ensure safety, regulatory compliance, and operational excellence. Our assessments are conducted in full accordance with NFPA 70E – 2024, IEEE 1584, and international best practices, making us a trusted partner for industries in Belgium. From on-site data collection to Incident energy analysis and safety label implementation, our comprehensive Arc Flash Risk Assessment process is engineered to protect people, assets, and productivity.

Why Conduct an Arc Flash Study?

An Arc Flash is a dangerous electrical explosion that can cause severe injuries, significant equipment damage, production losses, and even fatalities.

A professional Arc Flash Risk Assessment helps to:

- Identify potential hazards within your electrical system

- Minimize workplace injuries and operational downtime

- Ensure compliance with safety regulations

- Determine the appropriate PPE (Personal Protective Equipment)

- Label equipment with Arc Flash boundaries and incident energy levels

Scope of Arc Flash Risk Assessment

At VB Group, we conduct comprehensive Arc Flash Risk Assessments in compliance with NFPA 70E standards, ensuring both compliance and safety. Our services encompass a full range of activities from onsite inspections to power system studies and final reporting with onsite implementation.

Our Methodology

At VB Group, we follow a systematic and transparent methodology to deliver engineering excellence and safety assurance in every project. Our process integrates collaboration between clients and engineers, combining onsite Arc Flash risk assessments with in-depth technical Arc Flash analysis to ensure accurate, actionable, and high-quality results.

We conduct onsite Arc Flash training sessions to educate the client’s team on key findings, Arc Flash safety measures, and power system improvements.

Data Collection & On-Site Survey

Our Onsite data collection is a systematic and digitised approach. We begin with a joint kick- off meeting involving all stakeholders to align expectations, Define the scope, and outline deliverables. This sets the stage for a smooth and effective execution.

Our engineering team prepares and submits a comprehensive project schedule, outlining key milestones and timelines. The client confirms that the required plant person will be available in the plant to support site visits and data collection activities.

•

Onsite Data Collection with Image Documentation

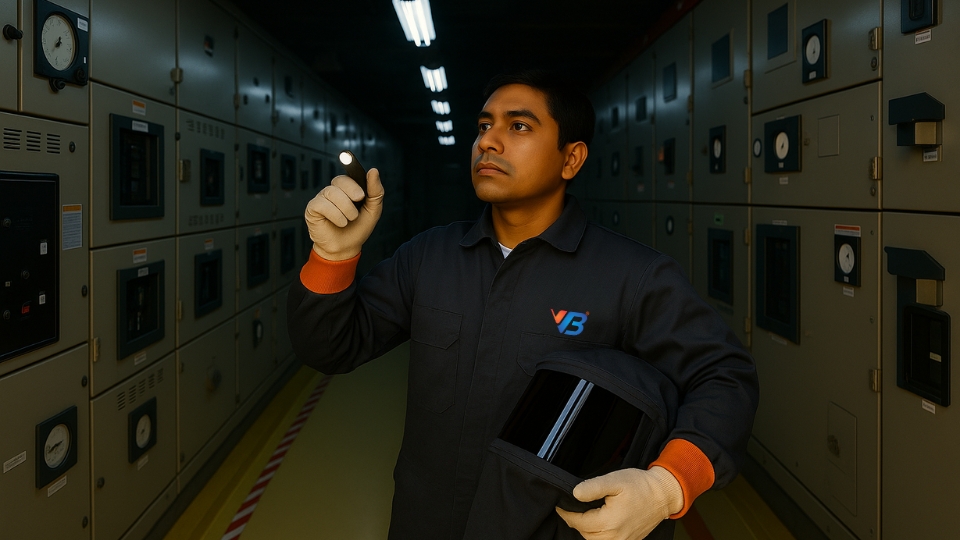

Our engineers visit the facility to gather critical data, including high-resolution images,

as per NFPA guidelines.

•

Data Digitalization

All collected data is systematically digitalized for record-keeping, validation, and future audits.

Our team uses a mobile application VB Tantra to collect all the required data of the site and captures the images of the installations and layouts as per the NFPA requirement guidelines. Our engineers visit the client’s facility to gather detailed data, critical for analysis and reporting.

Data Verification & SLD Preparation- Digitised Quality Check Powered with AI

Leveraging the VB Tantra mobile app, all data is instantly digitized and securely uploaded to cloud-based portals, enabling real-time access and review. This approach ensures a streamlined, transparent workflow from initial data collection to final Arc Flash analysis.

At the outset, VB Engineering conducts a meticulous site survey across the Belgian facilities, where trained engineers collect essential electrical system data, such as panel voltages, transformer ratings, breaker settings, and cable dimensions, along with photographs for verification. Based on the collected data and images captured a dedicated quality team will verify and analyse the data for quality powered with AI. Using the quality check approved data We develop Electrical Single Line Diagrams (SLDs) to map the electrical infrastructure.

•

Single Line Diagram (SLD) Preparation

We develop accurate SLDs using ETAP software, reflecting the current electrical

system layout. The one line drawings developed will be submitted to client for review

and approval.

•

Data Modelling in ETAP

The facility’s electrical infrastructure is modelled in ETAP to simulate real-time

behaviours and load conditions.

•

Library Building in ETAP

A component-specific Original Equipment Manufacturer (OEM) library is created in

ETAP, ensuring precise simulations and power system studies.

A joint review is conducted to verify the accuracy and completeness of collected data and Single Line Drawings. The client reviews and approves the SLD to ensure alignment with actual system.

Power System Modelling & Arc Flash Risk Analysis

Following onsite data collection, including image capturing as per NFPA requirements, all information is rigorously verified by VB’s quality team to ensure accuracy. Subsequently, engineers develop a comprehensive system model using industry-standard software, such as ETAP, SKM, Cymdist, easy power or other client-preferred tools to conduct essential power system studies, including Short Circuit Analysis, Relay Coordination studies, and Arc Flash studies.

Key System Studies Performed:

•

Short Circuit Analysis

Evaluates the fault current levels across the system to identify potential hazards.

•

Relay Coordination Study

A protective device coordination study including Relay coordination study ensures

that protective devices like relays and circuit breakers operate in a proper sequence

to isolate electrical faults swiftly and reduce damage.

•

Arc Flash Hazards Study

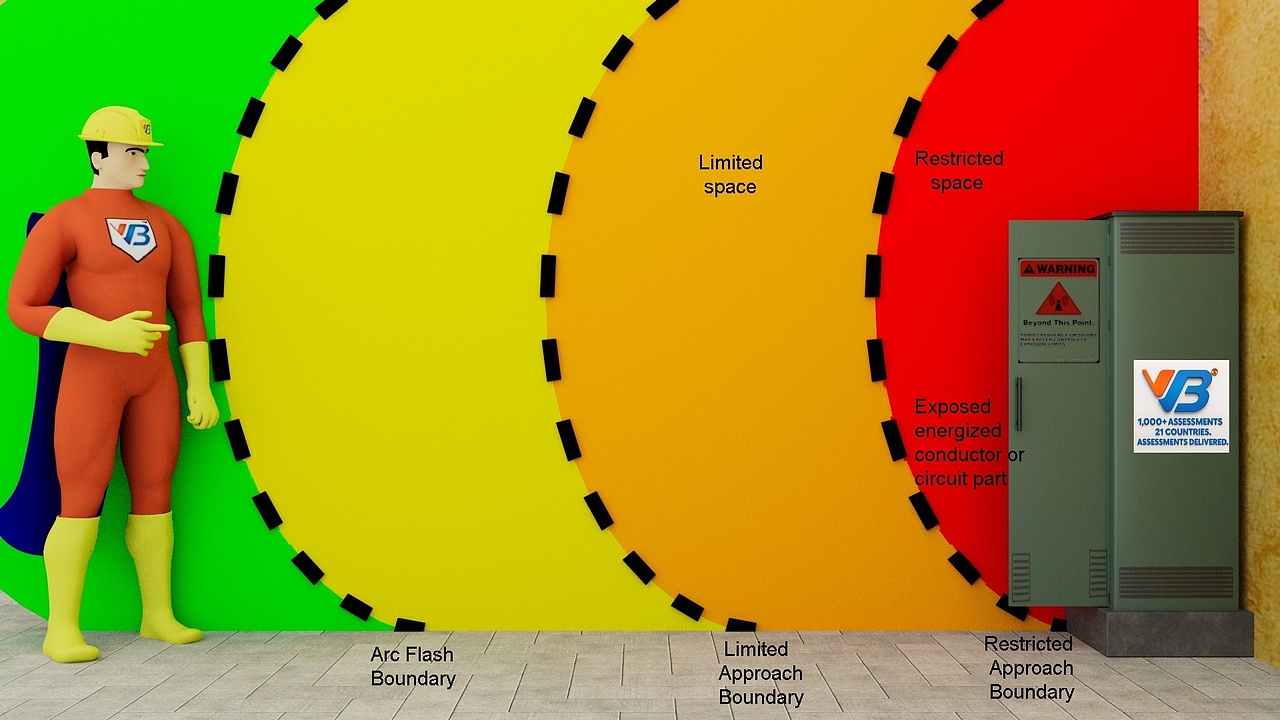

Determines Arc Flash incident energy levels, Arc Flash boundary distances, and

potential Arc Flash risks to personnel and calculate required Arc Flash personnel

protective equipment (Arc Flash PPE)

We perform thorough engineering audits, Arc Flash analysis, and power system evaluations based on verified data. These studies help to determine electric fault currents, incident energy levels, Arc Flash boundaries, limited and restricted approach boundaries, Arc Flash warning labels, Arc Flash danger labels and Arc Flash PPE category requirements ensuring full compliance with NFPA 70E, IEEE 1584, and IEC applicable European electrical safety standards.

Deliverables & Safety Implementation

Upon Power system studies and Arc Flash hazards, assessment completion, VB Engineering provides a detailed, customized report tailored to the facility’s operations as per Belgium and international statuary requirements. Our team compiles the findings and Arc Flash analysis into a structured Arc Flash study draft report.

Plant Condition Review and Safety and Engineering Recommendations

• We assess the existing plant condition thoroughly.

• Identify Arc Flash risks, non-compliances, and improvement areas.

• Provide remedial recommendations to enhance system safety and reliability.

Arc Flash Report Deliverables:

• A detailed Arc Flash Report outlining:

1.Existing Power system evaluation

2.Proposed Arc Flash safety measures

3.Power System Study findings and data interpretation

Arc Flash Report Deliverables:

• Soft Copies of Arc Flash Warning Labels for onsite display.

• Defining of Arc Flash Boundaries and Approach Boundaries for safe working practices.

• Arc Flash PPE Recommendations based on incident energy analysis.

This report includes one-line diagrams, Arc Flash hazard tabulations (such as incident energy levels and boundary distances), required PPE categorization, and recommended protective device settings. VB also supports Label printing and placement, prepares energized work permits in alignment with NFPA 70E protocols, and offers on-site training for internal teams. This turnkey solution promotes a strong electrical safety culture, helping to minimize risks, optimize operations, and ensure regulatory compliance within Belgian industrial or commercial environments. A joint session is held to discuss the draft report, clarify queries, and receive feedback. Revisions are made based on client feedback to enhance accuracy and usability.

The final report is submitted, incorporating all agreed changes and findings. Client formally approves the final report for implementation. As part of safety compliance, warning labels will be generated and supplied for use across the site.

Onsite Implementation of Arc Flash Risk Mitigation Methods

VB Engineering provides comprehensive onsite implementation of Arc Flash Risk Mitigation methods in compliance with global standards. Our scope includes deploying qualified personnel training programs as per NFPA 70E, enhanced through VR-based immersive learning to ensure practical understanding and retention. We deliver and implement Arc Flash Warning Labels and Arc Flash Danger Labels, including accurate printing and pasting at identified equipment locations. To further strengthen safety, we execute Arc Flash Boundary Marking across the facility, ensuring clear visibility for operational and maintenance teams. Our experts carry out relay settings correction and fine-tuning, optimizing system protection to minimize fault energy levels. Additionally, we support Arc Flash relay implementation to provide faster fault isolation and enhanced worker safety. Through this holistic approach, VB Engineering ensures your plant achieves world- class Arc Flash risk control, regulatory compliance, and operational reliability.

Protect Your Belgium Sites from Arc Flash Hazards

Ensure compliance with NFPA 70E, IEEE 1584 & IEC standards with VB, Engineering’s world-class Arc Flash Risk Assessments.

Need more information?

Contact us today to safeguard your people, assets, and operations.