Lean Manufacturing and Plant Design using 3D simulation with Data Analytics

VB Engineering is a pioneer in providing solutions for process improvement with the help

of lean tools. We have been offering various 3D simulation services with data analytics

and artificial intelligence for Production Improvement using process simulation and

virtual reality. Our offerings have enabled our clients towards Continuous Improvement

and made them ready for just in time manufacturing. Production improvement is always a

challenge including multiple parameters and various fields. The interdependency of the

production environment is highly complex and the only responsible person will be the

production person for the delay.

What is lean manufacturing? &

How do I adopt lean methodology is the burning question for every enthusiast in

manufacturing technology

Lean manufacturing has been a best practice across the globe in manufacturing process.

Lean production systems and lean manufacturing principles are adopted by all the world

class manufacturing companies. Canning and bottling lines are extremely complex and

difficult processes to manage, as they consistently run at very high speeds, where a

minor stoppage can have a big impact on performance and costs to the business. The

difficulty in creating an optimal packaging line design that would maximize production

and efficiency is greatly amplified when there are many different packaging formats

together with frequent changeovers. With packaging lines costing crores of rupees, an

increasingly competitive market for contract packaging and demand for multi-variety

packs, there is a clear need to maximize return by ensuring the equipment is being fully

utilized to maximize return. Therefore, when designing packaging lines, it is necessary

to have some means of predicting and explaining their performance and identifying the

influence of the key line parameters such as, SKU complexity, machine capacities and

their acceleration, running speed and deceleration parameters, conveyor speed and their

lengths, failure rates in MTBF and repair rates in MTTR.

The Filler Machine is the Slowest Machine

The filling machine is the most important machine, as it performs the primary function of

the packaging line which is putting the product into the container. It is also in most

instances the slowest machine in the production line. Therefore, on most packaging lines

the filling machine is called the core machine and the rest of the line is designed

around it. Usually the line efficiency is based on the capacity of the filling machine

and other equipment is sized to ensure, as far as possible, that the filler does not

stop, because of failures on the other equipment. This is done for both efficiency and

quality reasons.

Design Principle and Buffer Strategy

We being partner of Manufacturing process simulation software like Flexsim 3d Simulation

has been helping the world with best simulation modelling software techniques and data

analytics. Especially for food manufacturing dynamic simulation software are very

helpful for building the manufacturing simulation environment. The design principle for

packaging lines amounts to a buffer strategy, which makes sure that the buffers before

the core machine are almost full and the buffers after the core machine are partly

empty. This allows the core machine to continue in the case of a failure somewhere else

on the line. In other words, the core machine should have products at the in-feed and

space at the discharge. So when designing a high speed packaging lines a few variables

that influence the design are very important. They are a well-defined Buffer strategy,

Production speeds, SKUs and changeovers times, MTBF and MTTR and Line efficiency.

Buffer Strategy

This buffer strategy consists of two complementary elements. The first element is formed

by the buffers which provide accumulation. Static accumulation is achieved by putting a

real buffer between machines (e.g. an accumulation table or a crate store). Dynamic

accumulation is accomplished by the conveyors between the machines.

Production Speeds

The second element is formed by production speeds of the machines. The machines on either

side of the core machine have extra capacity or overcapacity. This overcapacity ensures

that the core machine has products at the in-feed and space at the discharge. This

enables these machines to catch up after a failure has occurred. After a machine has had

a failure and (a part of) the accumulation is used, then the overcapacity of the machine

is used to restore the system back to the situation before the failure. The machine

before and after the core machine have extra capacity with respect to the core machine.

The machines upstream of the core machine each have extra capacity with respect to the

next machine, and the machines downstream of the core machine each have extra capacity

with respect to the previous machine. This results in the 'V' -shaped capacity graph for

the line stages, with the filling machine at the lowest point. The above figure shows

the machine capacity graph (or V-graph) of a typical bottle filling line.

SKU Complexity

The third element is that today's food and beverage companies often use many different

product families or formats, with each product family having a set of specific processes

unique to it. SKUs are made up from unique combinations of products (varieties/flavors

or qualities), primary packaging formats and secondary packaging formats. For example,

in primary packaging, cans and bottles can be different sizes, different shapes and may

require widget insertion. Likewise, bottles may require caps or crowns; new glass lines

and returnable glass lines frequently merge so common equipment can be shared. Secondary

packaging may involve, for example, hi-cones, shrink-wrapping, a wrap-around format, or

even more than one of these options. To provide flexibility, it is possible to flow

products out of several primary packaging modules into several secondary packaging

modules. Optimizing the performance of a packaging facility becomes increasing

challenging as combinations increase and the number of SKUs multiply.

Efficiency

The efficiency of a packaging line is the percentage of the actual production versus the

possible production, for a given period of time. This is the number of filled bottles or

cans versus the possible number of filled bottles or cans in a specified time period. It

can also be defined as the percentage of the time that is theoretically needed to

produce the actual output (=net production time) versus the actual production time.

Line Efficiency

The line efficiency is a measure of the efficiency of the packaging line during the

period specified, and is calculated as follows:

Line Efficiency = [ (net production time) divided by (net production time + internal

unplanned downtime) ] x 100

The break up of all the times involved is shown in the diagram below.

Therefore, the time variables for estimating Line efficiency are 'Net Production Time'

and 'Internal Unplanned downtime'. And it is these two time variables used to determine

Line efficiency.

If the filler is the core machine, then the filler determines the line.efficiency.

Therefore, in the efficiency analysis of packaging lines the focus is on the loss of

production time of the filler or the core machine. Note that loss of production on the

core machine cannot be recovered, so the production time of the core machine determines

the (maximum) output of the line. To therefore increase the line efficiency that

considers all the above mentioned complex variables and conditions is not easy. It

therefore becomes necessary to study the whole packaging line in a 3D visual simulation

model, where all these variables and their impact on line efficiency can be examined to

bring out the following benefits. Increased throughput and efficiency by understanding

where the opportunities for optimizing machine speeds and in defining an optimum buffer

strategy. Provides a way to put a packaging system to the test in a risk-free

environment, uncovering bottlenecks and starvation in the system and revealing any

equipment that is not being fully utilized. Uncertainty and risk associated with major

business decisions involving complex processes is mitigated. Validate capital

investments that performance goals are realized at the minimum cost. Each machine can be

in one of six states·:

1. Running

A machine is running when it is producing, this can be different speeds and with

different reject rates.

2. Planned down

A machine has a planned stoppage as in the case the machine is stopped for planned

maintenance, changeovers, not in use, etc.

3. Machine internal failure

A machine has an internal failure when the machine stop is caused by a machine inherent

failure. There are often many different failure causes depending on the complexity of

the machine.

4. Machine external failure

A machine has an external failure when the machine stop is caused by external factors,

either caused by another part of the organisation (e.g. no supply of empties, no beer,

no electricity, etc.), or by the operator(s) of the line (e.g. lack of material such as

labels, cartons, glue, etc.) and waiting time.

5. Starved

A machine is starved (or idle) when the machine stop is due to a lack of cans/bottles or

cases. The machine has no input, i.e. the conveyor preceding the machine is empty,

because of a reason upstream on the line. Note that some machines can be starved for

more than one reasons, e.g. a packer can be starved for bottles and for boxes.

6. Blocked

A machine is blocked when the machine stop is due to a backup of cans/bottles or cases.

The machine has no room for output, i.e. the conveyor succeeding the machine is full,

because of a reason downstream on the line. Note that some machines can be blocked for

more than one reason, e.g. a de-palletiser can be blocked by pallets and by crates.

Hence, a machine is either running, or a machine is not running for anyone of above five

reasons. A simulation model will therefore predict the amount of time spent in each of

the above states and thus enable the designer to find ways to increase line efficiency.

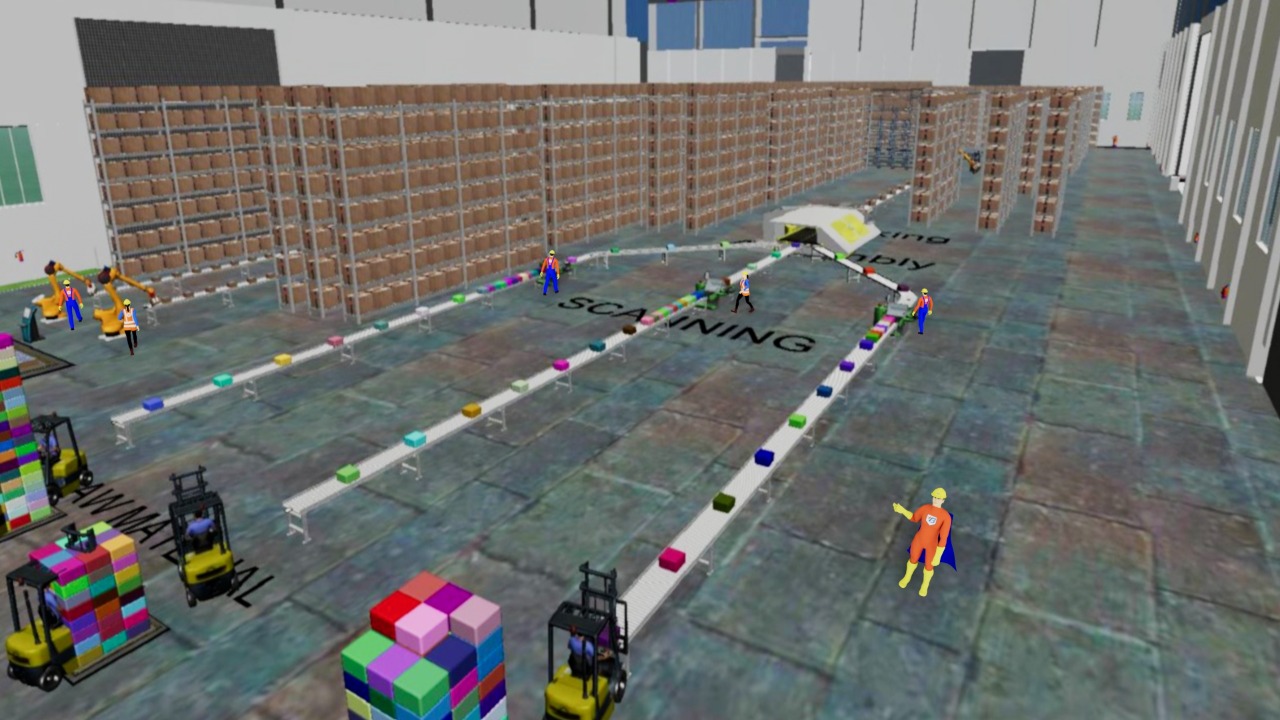

Simulation Model of Packaging Line

Simulation modelling is ideally suited for its unique time-based approach, in conjunction

with the ability to reflect the factors that vary, enable simulation models to

accurately mimic the complexities of a real-life packaging system. The objectives here

being to design the line to maximize the usage of critical equipment and maximize the

absorption of minor stops. Faster, more efficient packaging lines are able to respond

more quickly to market demands and lower raw material and finished goods inventory.

Companies need to take a hard look at the kind of tools used to analyse their core

business operations, especially involving large complex packaging lines. A decision

based on incorrect results can cost several crores of rupees or even hundreds of crores

of rupees, if we are dealing with large operations. The 3D design models built were

ensured to be lean six sigma compliant and the integrations of Logistics simulation has

taken the overall business game to the next level. The art of "Simulate today to see How

is tomorrow" has been mastered by VB Engineering with help of Artificial Intelligence

manufacturing software simulation techniques.