Core Advantages

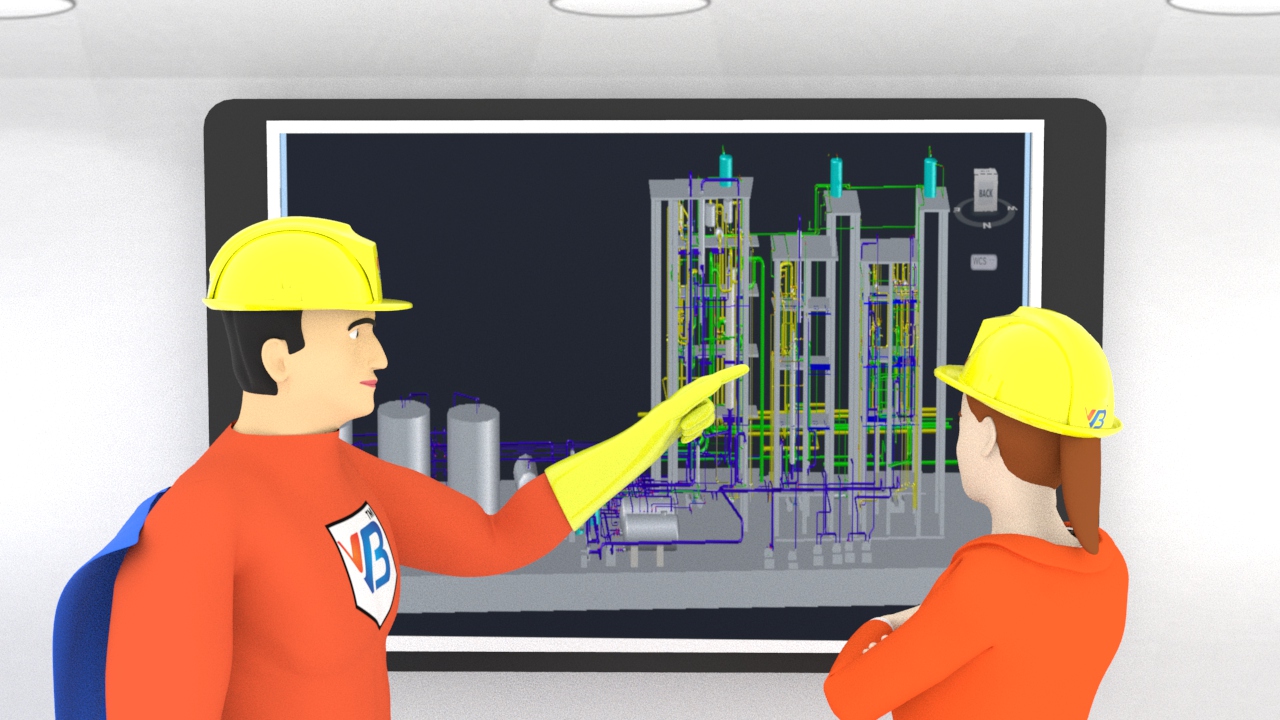

Scope

Initially for designing P&ID (Process flow drawings) designing collecting

data of selected process pipe lines with our experienced engineers and

designed the model with the collected data and listed the total equipments.

Read More

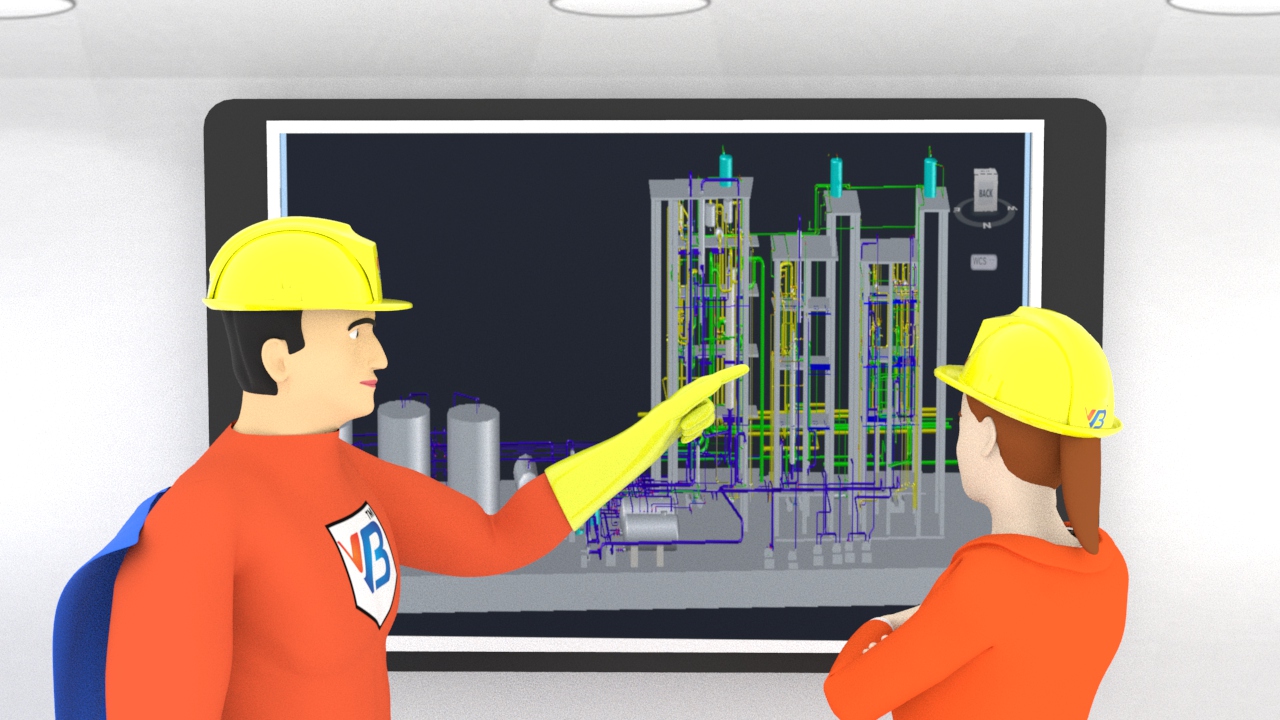

Software & Tools

We adopt digital range finders, vernier and tapes for measurements and

AUTOCAD Plant 3D software is used for designing P&ID.

Read More

Standards and compliance

We offer this P&ID service in compliance with Autocad Plant 3D PIP, ISA,

ISO/DIN and JIS standards.

Read More

Scope

Initially for designing P&ID (Process flow drawings) designing collecting data of selected process pipe lines with our experienced engineers and designed the model with the collected data and listed the total equipments.

Read More

Software & Tools

We adopt digital range finders, vernier and tapes for measurements and AUTOCAD Plant 3D software is used for designing P&ID.

Read More

Standards and compliance

We offer this P&ID service in compliance with Autocad Plant 3D PIP, ISA, ISO/DIN and JIS standards.

Read More