Data capture and pre-processing:

For simulation of manufacturing unit, we have to check the levels of input from

the client. For plant simulation we require the basic type of inputs from the

clients or the inputs we need to take from the site with our site engineers. The

details need in the designing of 3D plant simulation are the dimensions of the

layout up to the level of require accurate output as per site. Details of

equipments available on floor area with a basic detail for maintaining the

process design.

Modelling: generation/fitting of analytical surfaces

With the inputs the designing of plant in 3D will start modelling with available

data and also with our ideology of designing plant. Initially we need updated

layout with accurate dimensions as per site data or existing. Create the pillars

data and walls to get the basic structure. After the creation of total

structure, we need internal equipments and available floor space as per site if

existing or plan as per design idea. This results in the creation of 3D with

basic process flow as per our requirements.

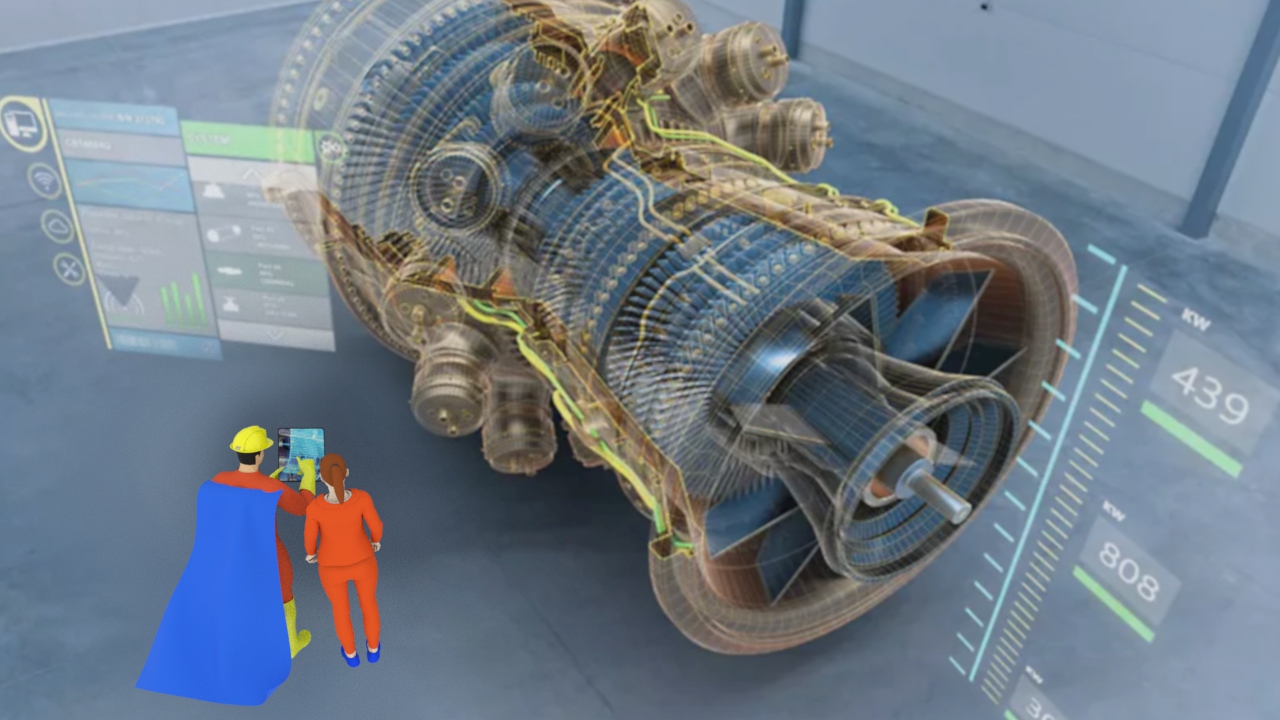

With final output 3D model, we need a simulation report for the analysing the output

production rate as per the real-time production sequence to get the arrangement in a

lean process. With the available data base after simulation using dashboard the output

of all the parameters has been analyzed and the reports has been analyzed with the

sequence of crated process flow. These reports include output, Input required, dwell

time of machine, total process time, stay time etc…, using pie and bar charts. The final

output gives the estimation and major requirements of existing plan results on reducing

waste of time and money gives better comparative profits