Our offerings

S L D Preparation

A single-line diagram (SLD) is a high-level schematic diagram showing how incoming power is distributed to the equipment. It is the blueprint for ...

Read More

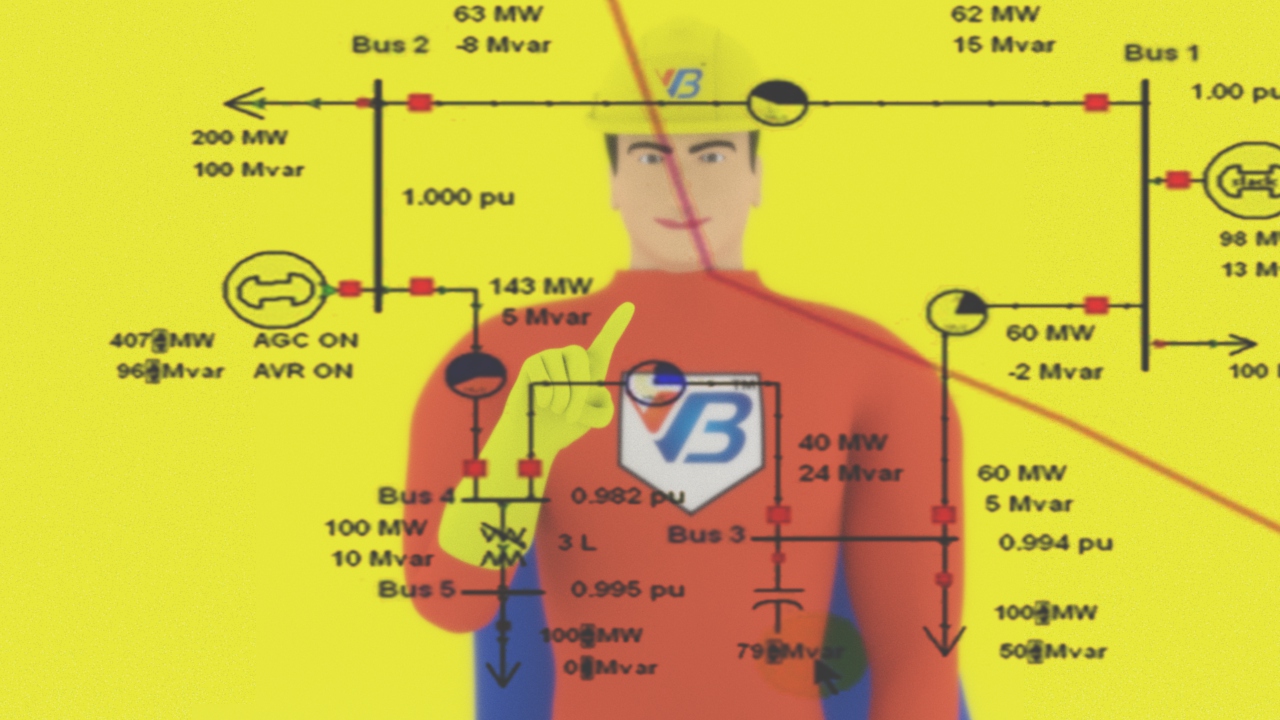

Load Flow Studies

Conducting load flow studies is an important requirement for the operations. The load flow analysis is an important part of the power system ....

Read More

Short Circuit Studies

Short circuit study is the process of analyzing an electrical system to determine the magnitude of fault currents that flows during ...

Read More

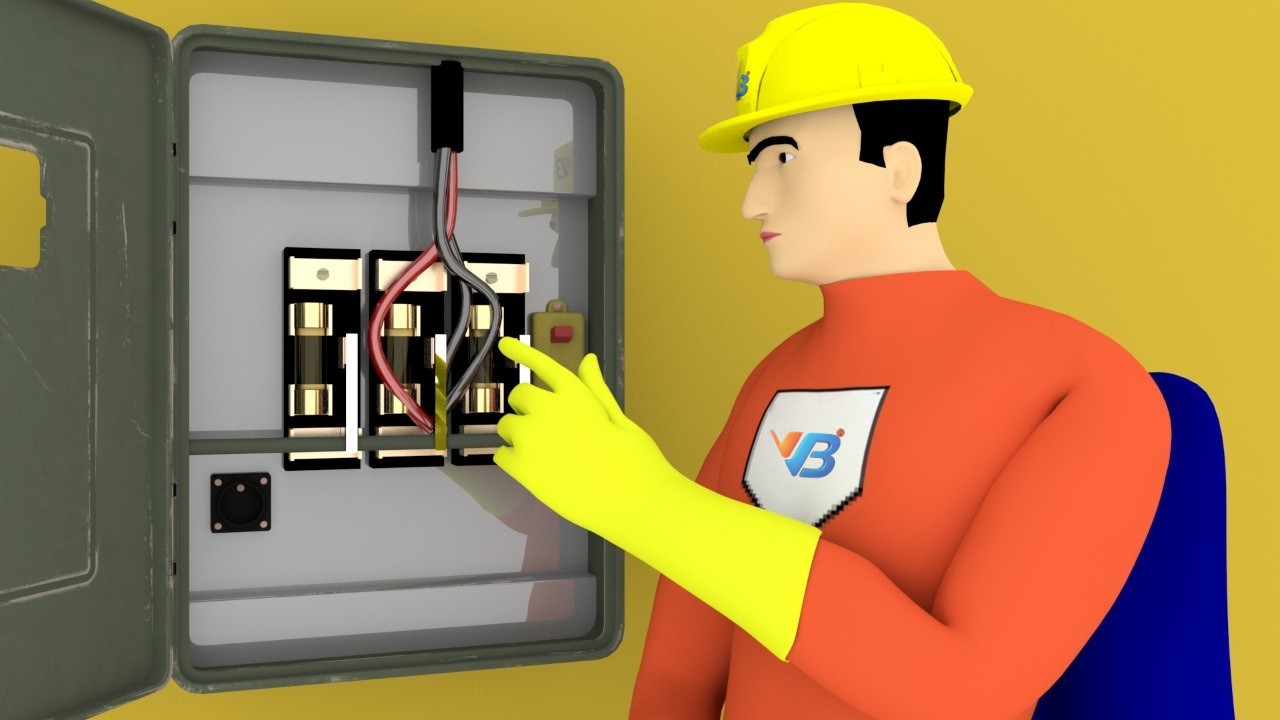

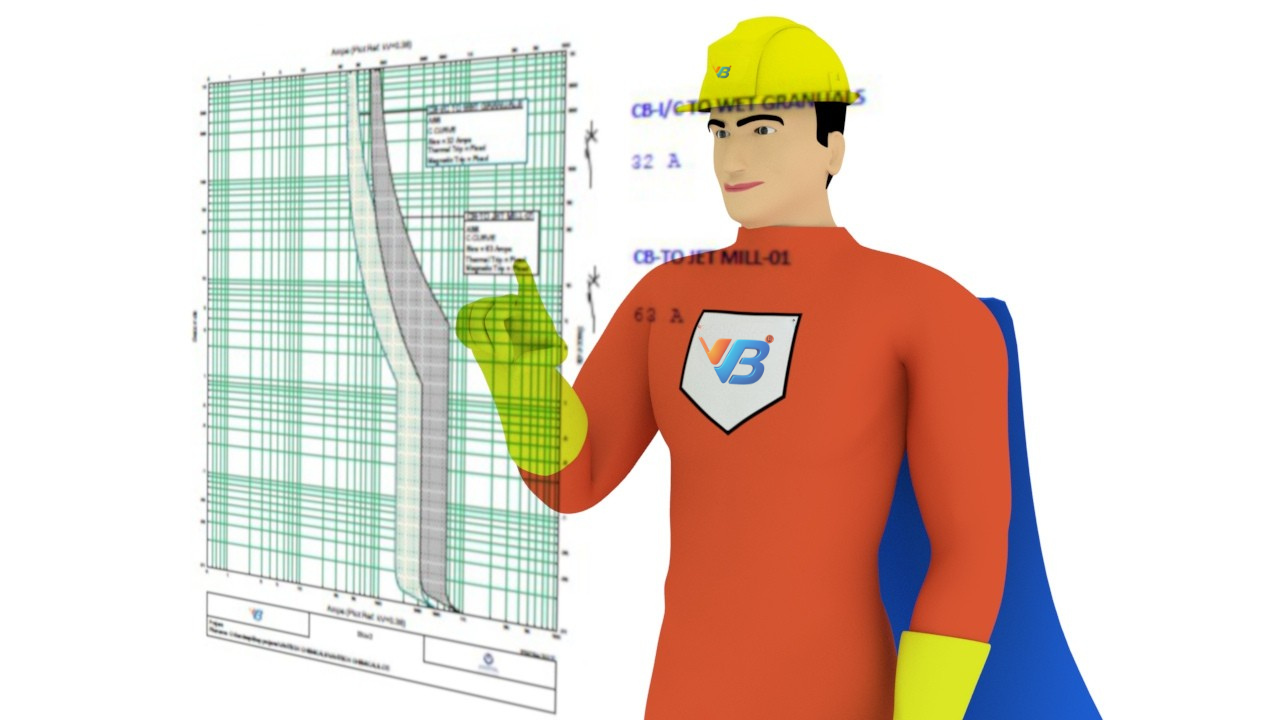

Protective Device Coordination

Protective device coordination is the very important part of design for a electrical network as a part of Power system .....

Read More

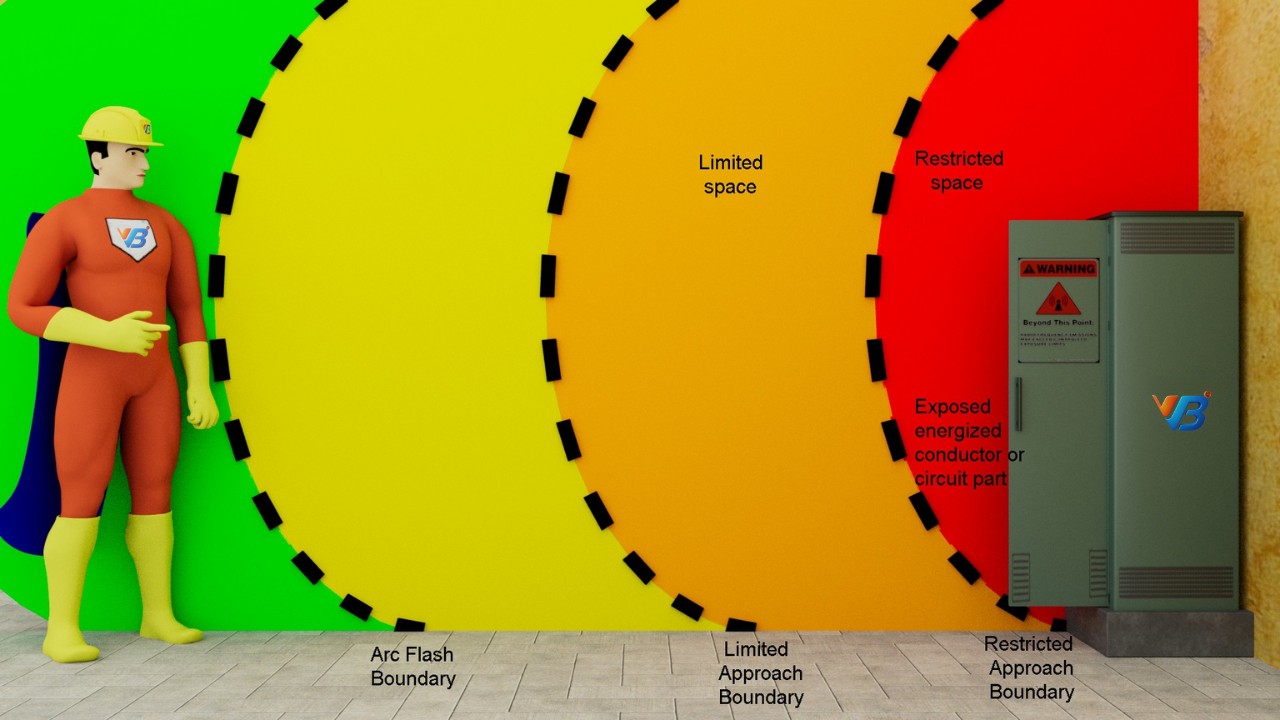

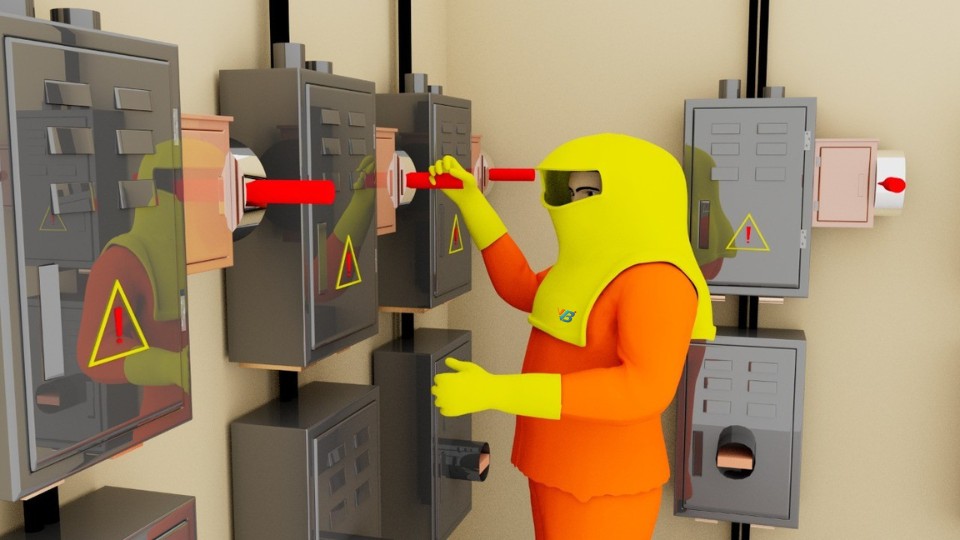

Arc Flash Risk Assessment

VB, is a leader and Arc Flash risk assessment partner for more than 500 global industries. Electrical Arc Flash is an electrical hazard present ...

Read More

Harmonic Analysis

Harmonic analysis is the process of identifying the harmonic distortions that occur ...

Read MoreArc Flash Study Standards & Compliance instead

The data of the circuit breakers, switch gear, transformers, feeders, fuses, type of grounding, MCCs through out the facility are acquired. From the existing data electrical drawings are verified. And in the absence of any Single line diagrams are developed. We deploy the data in software like ETAP, Easy power, TANTRA, SKM Power tools to develop the most contemporary and cost effective Single line diagrams. The inclusion of the data acquired in the field survey ensures that Arc Flash Risk Assessment is made possible at each of the equipment and the Arc Flash Hazard is identified at all possible circuits.

Planning to Conduct Arc Flash Analysis?

Arc Flash Hazards & Mitigations

Identify the causes of Arc Flash

In practical scenarios it is observed that Arc Flash is caused in cases of careless working

practices like unawareness on part of the working personnel, not using the required PPE for the

needed job, dropping of tools, creeping currents, rodent infestation, poor maintenance resulting

in the accumulation of dirt and dust. Failure of protective relays, circuit breakers, are also a

major cause of Arc Flash, switching actions like opening and closing the contacts of loads,

clamps etc. Damaged parts that need to be replaced, working on energised lines. As per NFPA 70 E

regulations, working on energised lines is confined to trouble shooting and testing conditions.

And in some cases where the deenergising of the line may have drastic effect on the production,

the companies opt to work on energised lines. It is the main responsibility of the management

rather than the manufacturers of the equipment to indicate the Arc Flash Hazard labelling on the

equipment.

Detailed Engineering Services

Our other engineering services may also help you

3D Factory Animation

We Build, Create and Animate the 3D models of the plants. Feel the Amazing 3D Walk Through of Your Plant. Its very simple. Let us know your ....

Read MoreS L D Preparation

A single-line diagram (SLD) is a high-level schematic diagram showing how incoming power is distributed to the equipment....

Read MoreShort Circuit Studies

Short circuit study is the process of analyzing an electrical system to determine the magnitude of fault currents that flows during ...

Read MoreProtective Device Coordination

Protective device coordination is the very important part of design for a electrical network as a part of Power system .....

Read MoreArc Flash Risk Assessment

VB, is a leader and Arc Flash risk assessment partner for more than 500 global industries. Electrical Arc Flash is an electrical ...

Read MoreArc Flash PPE

Arc Flash PPE is Arc rated personal protective equipment worn by workers performing maintenance on energized equipment ....

Read MoreHarmonic Analysis

Harmonic analysis is the process of identifying the harmonic distortions that occur in the electrical distribution system. VB provides turnkey ...

Read MoreLoad Flow Analysis for Oil and Gas

Conducting load flow studies is an important requirement for the operations. The load flow analysis is an important part of the power system ....

Read More2D CAD Drawings

2D drawing is a drawing that represents in only in X and Y-axis. More simply, a 2D drawing is flat and has a width but no depth or thickness.

Read More3D Isometric Manufacturing Drawings

3D or Isometric drawings means showing an object in 3axis (X, Y &Z) result in the replication of the exact designed product after manufacturing.

Read MoreFire Escape Floor Plan Drawings

Fire Escape Floor plan is one of the foremost providers of CAD services forget the people provide security and safety during working.

Read MoreP&ID Designing and Drafting

Piping and instrumentation drawing or P&ID Drawing is used to describe the total engineering process like from the source (Machine/Equipment) to ...

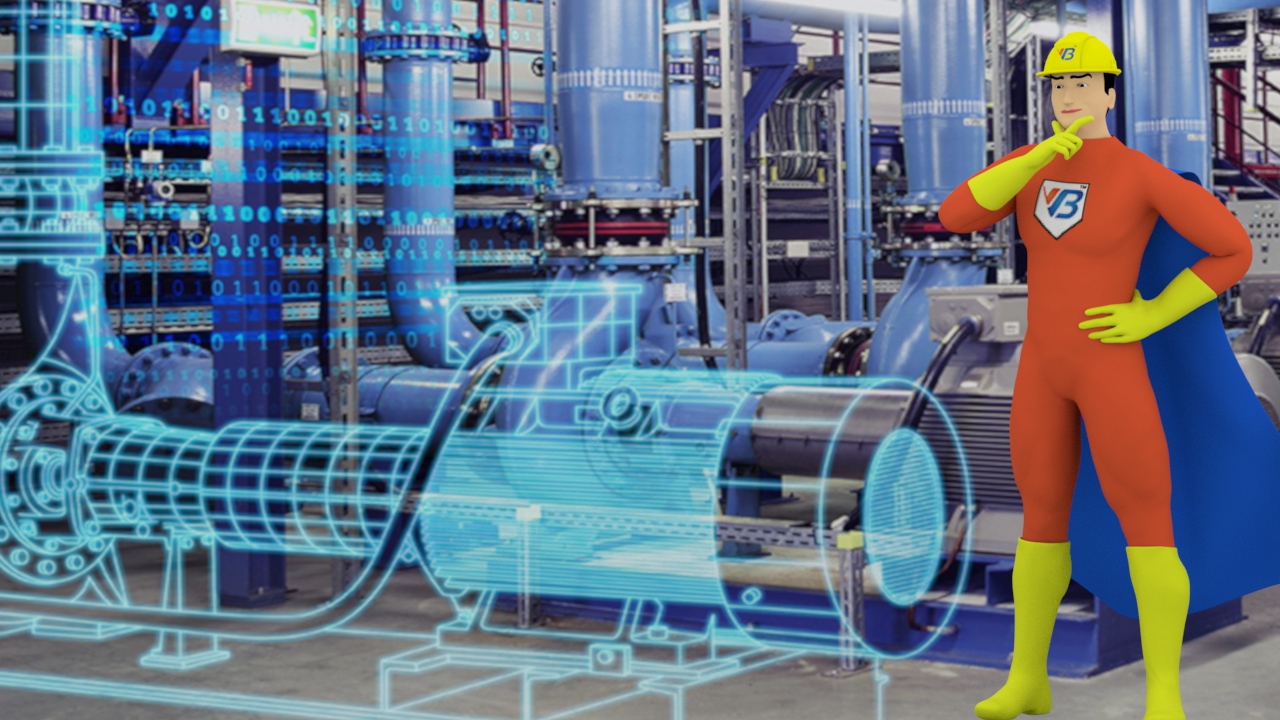

Read MoreReverse-Engineering

Reverse engineering is the process of discovering the technological principles of a device, object or system through analysis of its structure ...

Read MoreLean Simulation

A simulation methodology followed by the world class manufacturing units. Lean manufacturing has been a best practice across the globe in manufacturing process.

Read More3D Plant Simulation

Planning, designing and modelling of a system by simulation before the real time implementation is the present-day trend.

Read More